Packaging Solutions by IMA Safe

ON SHOW

GIANT in Containment

Blister packaging machine

Advanced technology, stunning design, highest efficiency ensured by SOMBRERO feeding system: everything you can expect from GIANT blister machine. Configured with containment application, GIANT allows the operator to work with the most dangerous products as well.

Come and discover the last 4.0 solutions: we will provide visitors with a size changeover in Augmented Reality.

UNILINE

Integrated counting system

UNILINE, every function required for a complete counting line, in a single machine: container loading, desiccant insertion, counting and filling, cotton insertion, capping, rejection.

To achieve the highest level of count accuracy, UNILINE can be equipped with E.F.S. counting technology.

C102V

Tray packaging machine

Are you looking for the ideal tray packer in terms of quality/price ratio?

C102V is the perfect choice, whatever product you need to pack. IMA PG has developed a wide range of feeding solutions depending on customer request. The machine is extremely simple to use for semi-skilled operators too.

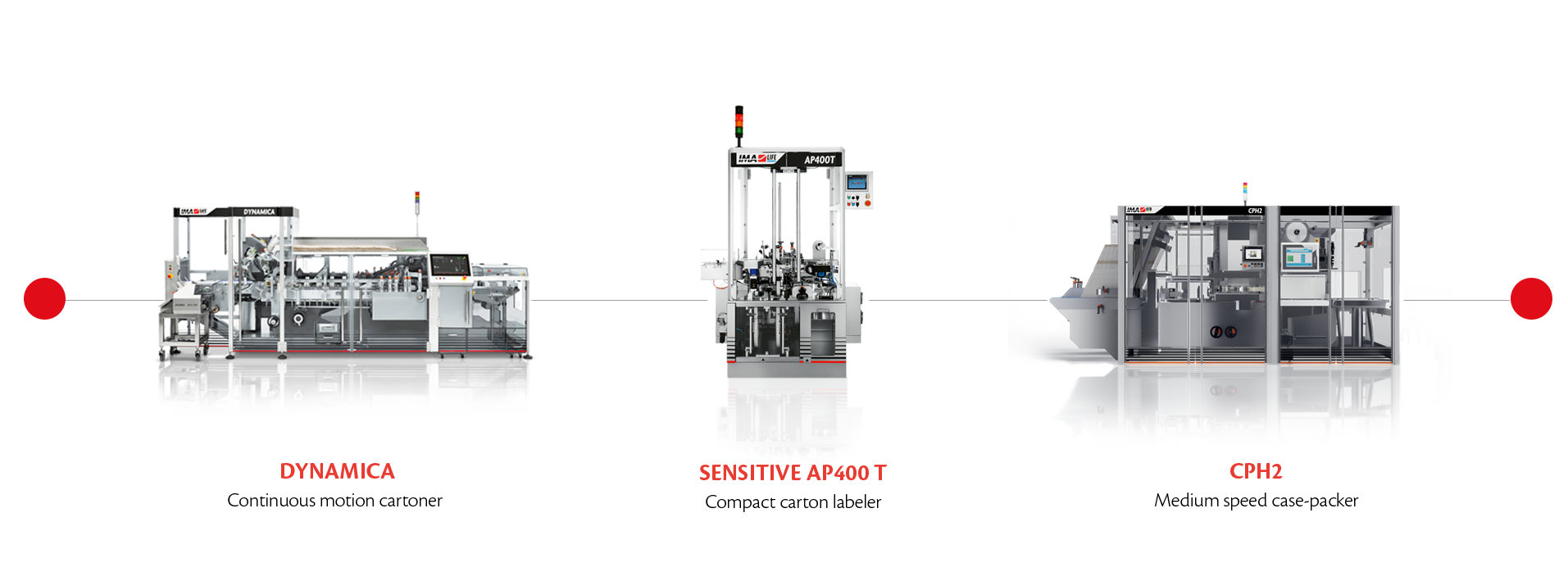

DYNAMICA, SENSITIVE AP400 T, CPH2

Integrated Packaging Line for Pharma

DYNAMICA cartoner, SENSITIVE AP400 T labeler and CPH2 casapacker:

IMA, one time again, demonstrates its capacity to supply complete packaging lines

able to meet the stringent requirements of the pharmaceutical industry.

In line: DYNAMICA

DYNAMICA is the ultimate expression of flexibility in carton packaging, featuring a huge variety of feeding systems, carton sizes and applications.

The new version has been revised to be as ergonomics as possible for the operator, remaining extremely compact.

The machine on show is equipped with new hot and cold glue closure for tamper evident and integrated module for printing and checking of serialization code.

In line: Sensitive AP400 T

The new SENSITIVE AP400 T, carton labeler and T&T unit, is the smallest new release in the array of AP400 labellers. The machine on show applies the tamper-evident sealing on one carton flap, while printing Data Matrix code with a printer on the other flap of the carton, previously glued.

A camera vision system for data reading and checking enables the Tracking & Tracing of all the labelled cartons, ensuring transparency in manufacturing and safeguarding product authenticity.

In line: CPH2

The CPH2 is a fully automatic casepacker designed specifically to handle the widest range of products and materials used in pharmaceutical.

The machine has been built to maximize efficiency and ease of use in an ever increasingly demanding work place, to guarantee complete line clearance and to ensure total access to all modules.

Flexibility, maximum efficiency, total access and total control make the CPH2 a casepacker of new generation, capable ofsatisfying all of your current and future case packing requirements.

IMA Digital: make it real.

Smart Machines. Smart Services. Smart Organization.

Come and see the IMA Digital Hub Data Services for machine data visualization and analysis as well as machine monitoring tools. Innovative AR solutions for size change over operations and immersive VR systems for operator’s and maintenance training will enhance Operational Excellence to ensure continuous growth of productivity.

IMA Digital shapes its vision of Smart Machines and the Smart Factory declining the Industry 4.0 principles according to a unique visionary approach.

IMA Digital will deliver additional value with empowered machines and services created to supply predictive and personalized customer experiences across the entire value chain.

Based on the common principles of Industry 4.0, IMA Digital will offer Pharma the opportunity not only to fix agility and productivity issues, but also to provide quality operations with better instruments to enforce product safety and supply chain security.

IMA’s vision of an intelligent factory is a place where the main production elements (tools, devices and machines) are connected in order to obtain a smoother production management, allowing higher flexibility and reconfiguration.